Improving productivity in industrial automation systems: Windows Server for Embedded Systems

Posted By Partha Srinivasan

Product Manager, Windows Embedded Server and SQL Products

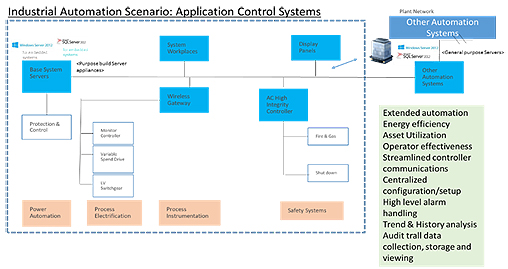

In my last blog, I covered how Windows Embedded Server-based server appliances are used in the retail industry as in-store servers to generate business intelligence; in this blog, we will see how server appliances are used in the manufacturing industry, specifically in industrial automation, in roles such as historian servers, and application controllers that can improve productivity, asset utilization and operational efficiencies.

With historian server appliances based on the Windows Embedded Server platform, industrial manufacturing plants can gain valuable information by connecting and analyzing historical and ongoing process data generated from the plant. Both archiving and plant-wide accessing in real-time enable rapid decision making based on assured data – producing greater productivity and lower costs, thanks to improved business intelligence. The meaningful consolidation and aggregation of data into valuable information can enable dynamic reporting, such as downtime reports, alarm summaries for maintenance purposes, consumption data and energy balances, and efficiency reports of the different production lines. Combined with Microsoft SQL Server, database management systems provide a reliable and protected database platform for historian server appliances. An end-to-end enterprise connectivity solution built using industrial server appliances — that spans from production-line sensors to IT datacenters – provides instant access to factory-floor data enterprise applications, improving the production process optimization and overall factory productivity.

Windows Embedded Server appliances are also used as application controller systems that can extend automation capabilities and improve asset utilization, energy savings and operational effectiveness. They are also used for streamlining controller communications, providing centralized configuration, and for high-level alarm handling. These industrial server appliances are also used for performing trend and history analysis to improve the precision and predictability of systems, as well as for auditing trial data collection, storage and viewing. Further, capabilities such as fail-over functionality and flexible storage-management options are key, as is a long lifecycle, which allows industrial automation OEMs and customers to build automation and application control systems that last.

To read more about how intelligent systems can transform the industrial automation, visit our manufacturing page; more about Windows Server for Embedded Systems is here; and read about the release of our newest platform, Windows Server 2012 R2 for Embedded Systems, here.

To read more about how intelligent systems can transform the industrial automation, visit our manufacturing page; more about Windows Server for Embedded Systems is here; and read about the release of our newest platform, Windows Server 2012 R2 for Embedded Systems, here.