University of Cambridge and Hololens On-Site Virtual Mapping Can Aid Inspections

Guest blog by Dr Ioannis Brilakis and Marianna Kospida University of Cambridge & Catherine A. Cardno, Ph.D. from the American Society of Civil Engineers

Researchers at the Laing O’Rourke Centre for Construction Engineering and Technology at Cambridge University have been working to merge four-dimensional virtual design models with site visits to enable inspectors to conduct hands-free, paper-free inspections on construction sites. The fourth dimension, time, is made possible by a schedule-dependent system that indicates to the inspectors which portions of the project should be complete depending upon the date they are on site

“Progress-monitoring inspection is laborious, time consuming, and error-prone,” says Marianna Kopsida, a Ph.D. student and a Marie Curie fellow in the university’s Construction Information Technology group.

Typical inspections require site visits where inspectors must conduct visual inspections referencing drawings and databases, take photos, and then return to their offices to fill out multiple forms and write reports, Kopsida explains. This multiple-phase, multiple document process can also be subjective, depending on the inspector’s education and experience.

“What we are trying to do is to automate the procedure, so that we can save time and effort for the inspector,” Kopsida says. “[Automating] this information [also] allows the inspectors to detect any scheduling discrepancies and take timely corrective options that will prevent time and cost overruns of the project during the construction phase.”

“The whole purpose of this technology is to make people’s lives easier, and make the work more consistent, especially when it comes to inspection,” adds Ioannis Brilakis, Ph.D., a Laing O’Rourke Lecturer at the university, Kopsida’s doctoral advisor, and the leader of the group in which she studies. “[Inspection] guidelines themselves are very vague. There is a huge room for interpretation, and we have study after study showing how you can send two different inspectors to do the same job, and you’re very likely to get different answers,” he notes.

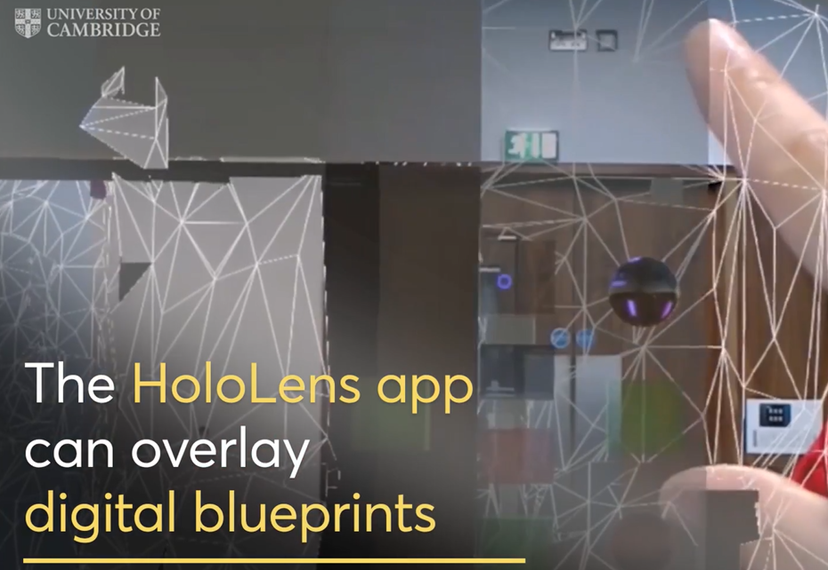

Kopsida has tested numerous so-called “mixed-reality” headsets that allow the user to simultaneously see both the virtual elements of a building design model (BIM) and the real world. She has found that for the purposes of progress monitoring--which needs to be able to monitor what is supposed to be present on site at a certain time, but might not yet be—Microsoft’s HoloLens’ system works the best.

When an inspector arrives on site, he or she will put on glasses similar to construction safety glasses. By looking at the floor, walls, and ceiling the inspector will “register” the room and initiate tracking. Within 30 seconds, the system will determine in which direction the user is looking, the size of the space, and in what area of the design model he or she is standing. The system will then automatically size the model and overlay them onto the room, according to Brilakis. Wherever the inspector walks from that point, the system will indicate what elements of the project should be completed according to the building’s design model.

“Augmented reality has still many challenges, and one of them is the tracking of the position of the user and the registration in order align the virtual data with the real data, so this was the main challenge of my research,” says Kopsida. Microsoft HoloLens “gives a more intuitive solution, so you actually interact with the virtual model, it’s hands-free, and you feel that you are actually inside the model,” she says. “It’s more intuitive and more interactive compared to having a tablet and seeing a 3-D model on a 2-D screen, so it offers a whole new experience.”

The system inputs BIM files—any BIM file provided by an architect for a particular building, according to Brilakis. Before the inspector comes to site, he or she can preload an inspection plan so that just those types of elements will be displayed. On site, the mixed-reality system will then direct the inspector to each one of those elements in turn. Because the system is schedule-dependent and working in 4-D, it will immediately identify where elements, such as columns, might not yet be built even though they should be. “[The system] automatically updates the progress information back into the design model, so that on top of the expected date of completion, you have the actual status of completion at the time that you are doing this walk through,” Brilakis says. The system automatically detects both volumetric changes, like columns, and textural changes that would indicate which finishes, such as carpet, have or have not yet been installed.

The researchers have also discovered an unintended benefit of using this type of virtual inspection system for real-world construction projects, which is able to collect more precise information than inspectors would be able to do physically, according to Brilakis. “Design models are never exactly like the real building,” Brilakis explains. There are always minor variations in sizes and dimensions on a construction project. “So, if I match my design model to the nearest walls of where I’m standing [when I enter a site], if I go to the other end of the building, chances are it will no longer be a match,” he says. “That’s a good thing, because it gives the inspector an idea how far off the real world is from the design model.”

Brilakis’ group is working closely with Trimble and construction-industry users to integrate technology with existing work flows, because the industry is inherently conservative about changing processes. “What we’re trying to do is integrate the technology within their existing work flows, to take those work flows and just make them shorter, faster, and more enjoyable, and to remove the tedious parts that people don’t enjoy doing,” he says. “Once you try to focus on these types of areas, then you can create solutions that people will try and very easily, within seconds, be able to say, ‘Yeah, I can see a value for this. I know how this will help my work.’” “That’s the biggest achievement,” Brilakis says.

To learn more about what the team at Cambridge are undertaking see the short video