Inbound pick-and-drop (inbound staging) in Microsoft Dynamics 365 for Operations

Scenarios

There are several usage scenarios in the inbound pick-and-drop process.

Imagine that the aisles in the warehouse that warehouse workers use to get to put-away locations are very narrow because companies want to save floor space and store as many items as possible. This often requires dedicated equipment and warehouse workers who are trained to operate in these aisles for both picking and put-away operations. In this situation, locations outside the aisles are created and served as both inbound and outbound pick-and-drop locations. If the production results in the fact that the produced items need to be put away in the evenings, production workers might move all items to the pick-and-drop location near aisles and leave them for the dedicated warehouse workers to put away.

The process is the same for received purchase orders. A receiving clerk picks the orders at receiving docks and move them to the pick-and-drop location where final put-away will be processed.

We will use the purchase order receiving as an example to show how to work with inbound pick-and-drop.

Next, we show how inbound pick-and-drop can be set up in Microsoft Dynamics 365 for Operations.

Set up inbound pick-and-drop

Setup scenario

Imagine this simple scenario: there are 3 aisles with 1 pick-and-drop location in each aisle. Note: This is a simplified scenario. Normally, there are several pick-and-drop locations in each aisle.

In the front of each aisle, there is a pick-and-drop location acting as the staging location for the aisle. Each staging location and the locations that it serves are defined as the members of the same zone. We will use the Zone ID from the Temporary Work Transaction table to differentiate work templates.

What we want to achieve is that a pick-and-drop location is selected per the selection of the final put-away location. So, we will create 3 zones and 3 fixed item locations for 3 different items, 1 item for each zone, and we will create 3 pick-and-drop staging locations, 1 staging location for each zone.

Note: You can use other filtering than fixed item locations, such as product groups or vendors, to set up items in 3 different zones.

We will create 3 different Location directives as well for put-away and they point to the staging locations that are associated with directive codes.

In total, we will have 3 work templates. Each work template has 1 zone and a dedicated staging pick-and-drop location.

Setup procedures

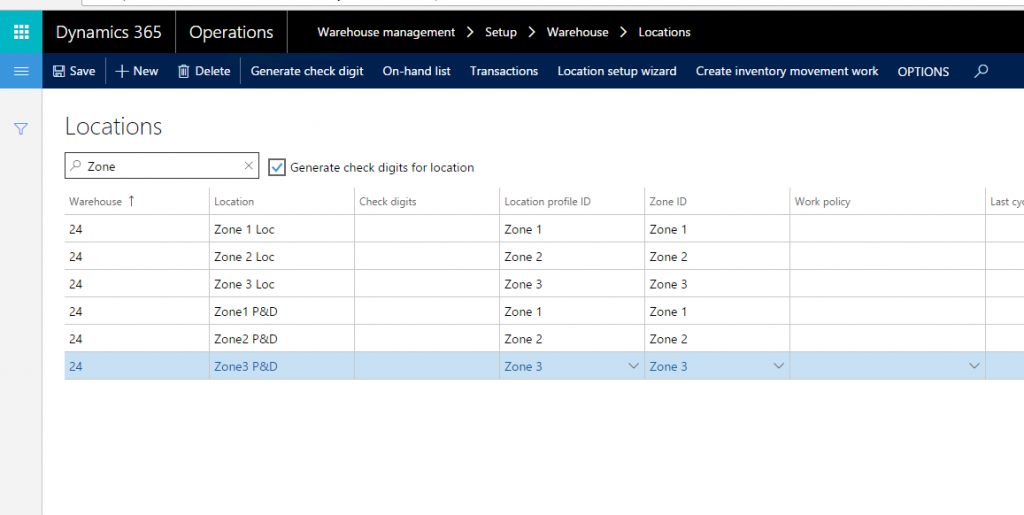

First, we create 3 locations for put-away in each zone and 3 dedicated staging pick-and-drop locations for each zone. Note: We can have many locations in each zone. This simple example just illustrates the process.

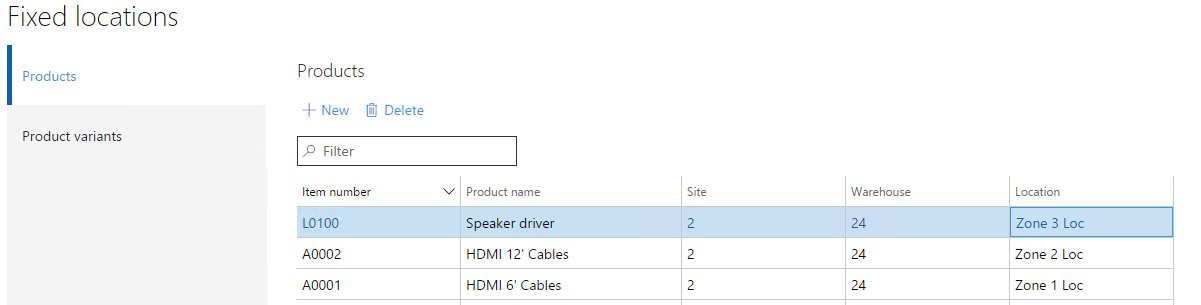

Next, we set up fixed locations for 3 items with 1 item in each location in each zone. This is not mandatory, but this is the way that we use to have items to be allocated to 3 different final locations in 3 different zones where we want to stage pick-and-drop locations prior to final put-away.

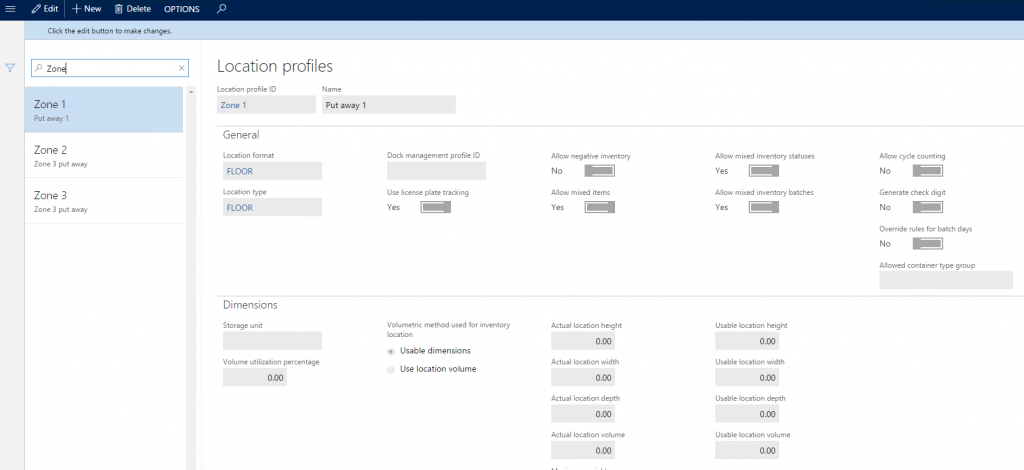

Next, we create 3 Location profiles that will be used in Location directives, but this is not mandatory. If the properties are the same, you can use 1 Location profile for all Location directives

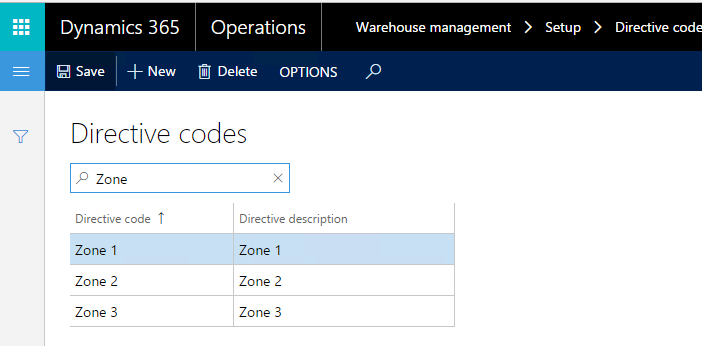

Next, we create 3 different Directive codes that will be used to associate Work template and Location directives with dedicated staging pick-and-drop locations for each zone.

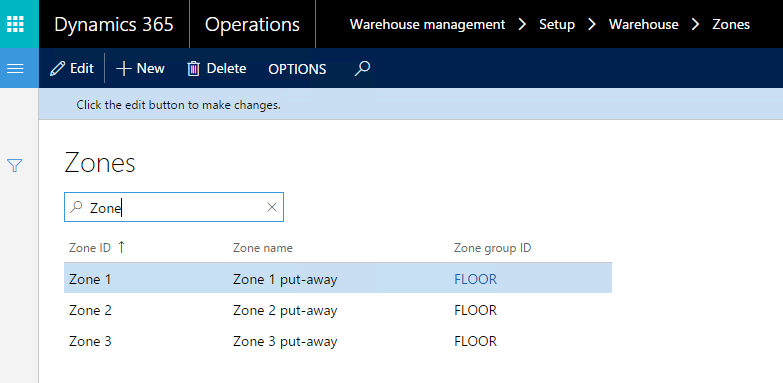

Next, we create 3 different zones to which we allocate the locations that we have created in the previous procedure.

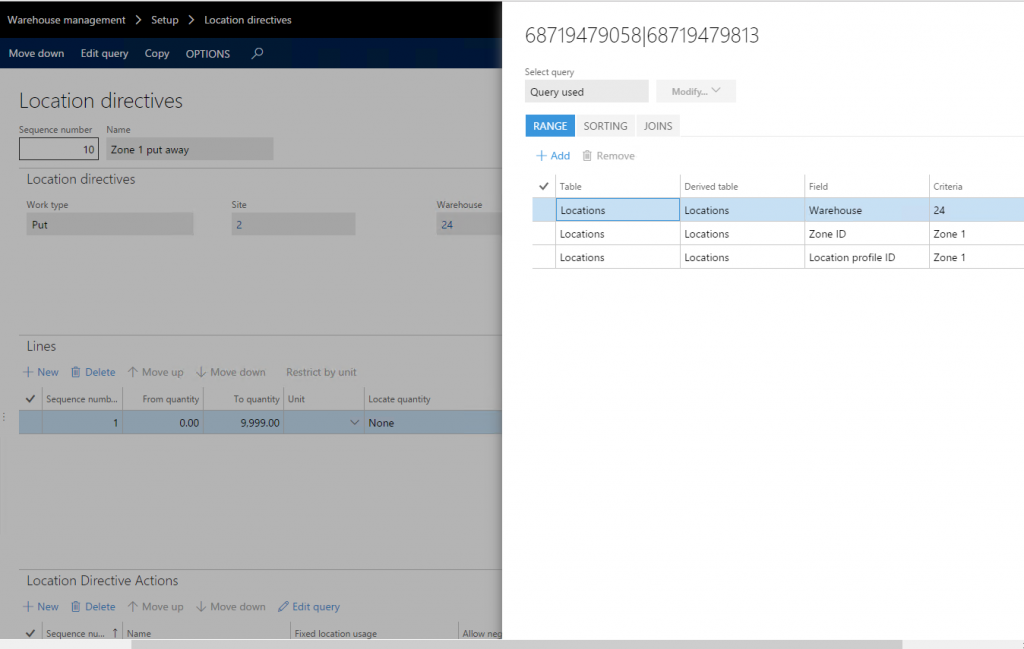

Next, we create Location directives for each zone. We use Fixed location because we have fixed locations.

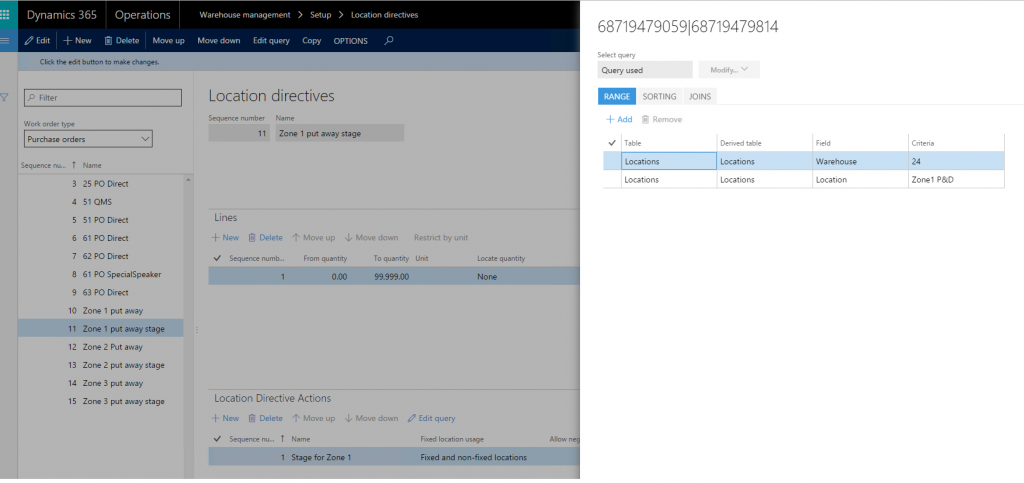

Next, we create 3 Location directives, 1 for each staging pick-and-drop location associated with a dedicated zone.

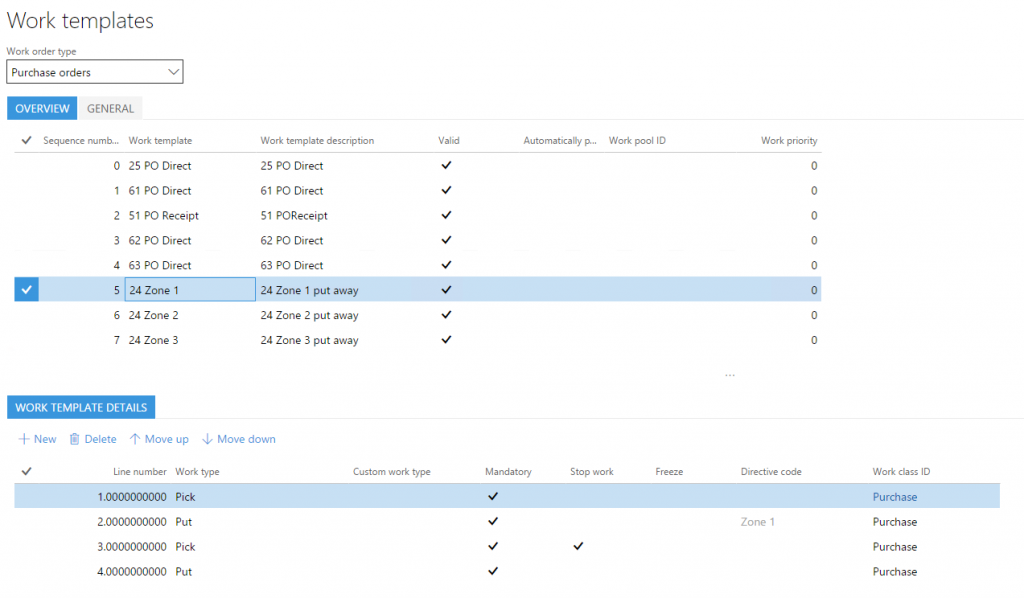

Next, we create 3 Work templates. Each template includes 2 pick-and-put steps. The Work templates are associated with location directives using the directive codes that we have created.

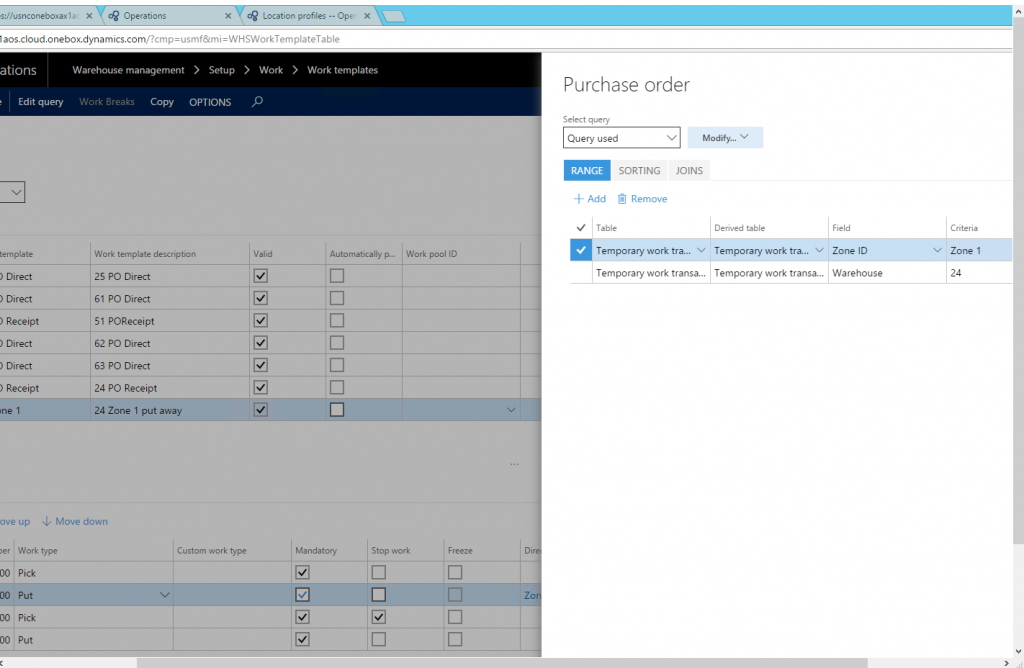

Next, see the following query setup for Work templates.

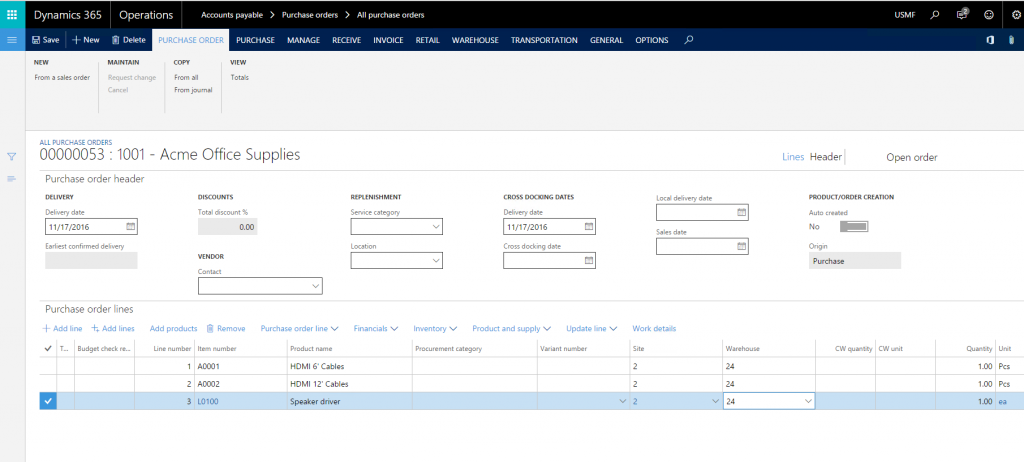

Next, we create a Purchase order for 3 different products. For each product, we set up a fixed location in one of the 3 zones that we have created.

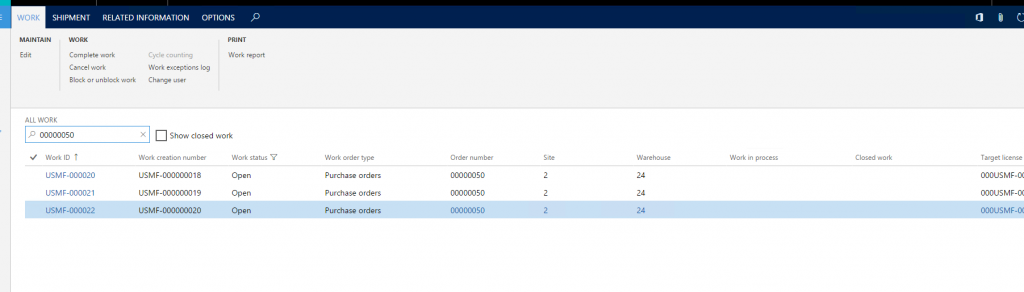

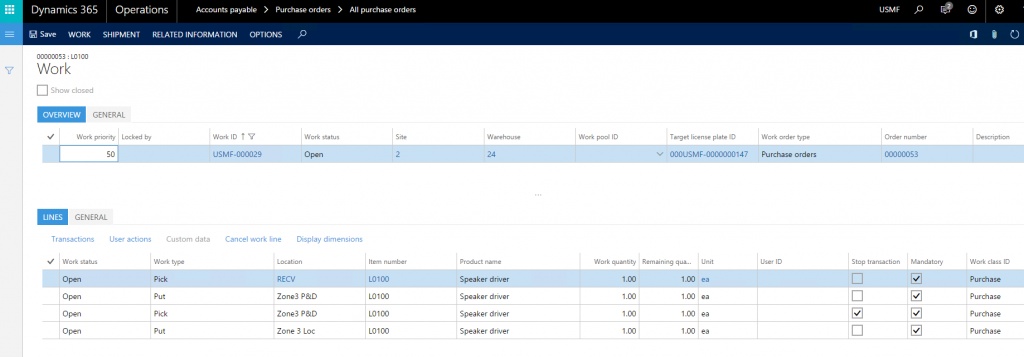

After we receive the purchase order using barcode scanner, we can see that 3 Work IDs are created for 3 products. Each product has its own unique Work ID.

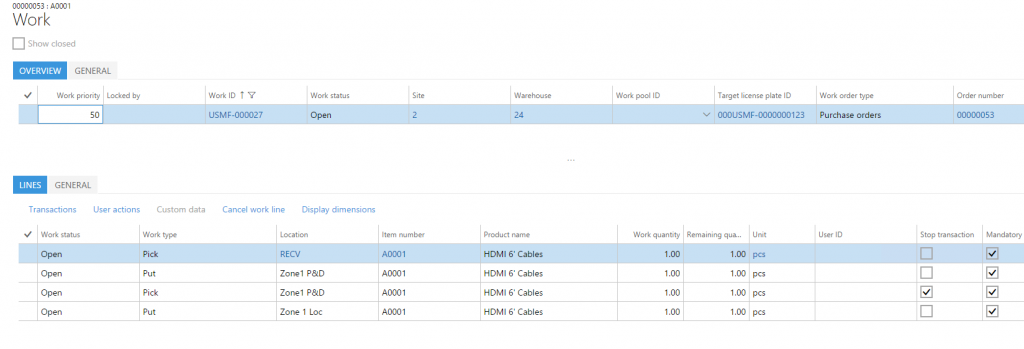

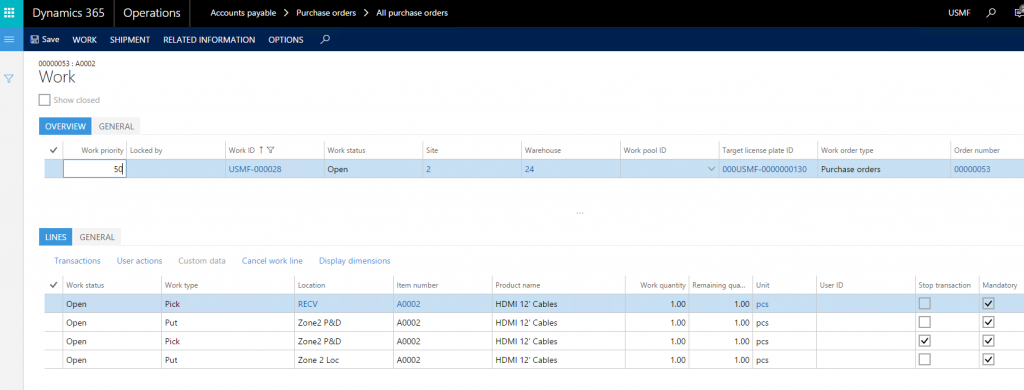

We can see that each item has two pick-and-put steps using their respective staging pick-and-drop locations.