Product Scanning Confirmation

Introduction

In Microsoft Dynamics AX 2012 R3 it is possible to enable location and quantity confirmation during work processing through the RF device. Currently with the cumulative update 8, this has been extended to support product confirmation too. In this case the warehouse user will need to confirm that he is processing the right product for each work line. For cases where there are warehouses with mixed products in one location or products with multiple variants it can be hard to distinguish them leading to costly mistakes if wrong items are picked.

The warehouse worker needs to scan a unique identifier in the “Product Confirmation” field so that it can match with the work line that is currently being processed. The following identifiers are acceptable, depending on the product.

-

Item id: Only for distinct products, since this does not uniquely identify a product master.

-

Item Alias: Only for distinct products, since this does not uniquely identify a product master.

-

Bar code: Both for distinct products and product masters. Details are shared in a separate section of the blog post.

-

External item Id (CustVendExternalItem): Only for products, since this does not uniquely identify a product master.

-

GTIN code: Both for distinct products and product masters (currently this process works the same as the bar code)

Consider as an example the product master “Towel”, which has 3 sizes: small, medium and large.

Setup

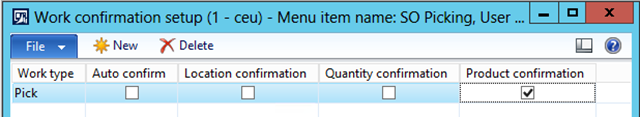

The product confirmation functionality takes action per process and requires a specific setup in the related menu item. For example, if you have a Sales Order picking menu item, you would need to open the work confirmation setup form for this specific menu item. The “product confirmation” checkbox needs to be selected together with a specific work type, which for this functionality either can be Pick, Put or both.

You can define this setup for any menu item, but it will not have an impact on all of them. Product confirmation makes only sense when there is some work already created for the process that the warehouse user is trying to execute (eg. Sales order picking). If this is not the case, such as Purchase order receiving, then you can still configure the same setup but it will not take any action.

For example, let’s assume that you have enabled the product confirmation when executing the Pick part of the SO picking process, like in the picture above.

Product confirmation gets enabled when there is only one item on the work line which is being processed. There are cases during both picking or putting, when you need to process multiple items at once. For example, during Sales order loading from the Stage area, if you need to pick multiple items the RF displays “Item: Multiple”. In this scenario it is not possible to do product confirmation (eg. to confirm each of the items one by one). You are able to setup the work confirmation, even if you work with multiple item pick, but it will not be effective and will not generate warning or error message.

Product Confirmation using bar codes

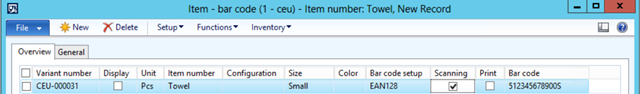

If you need it, you can specify multiple barcodes for each released product/variant (Manage inventory -> Bar codes) and each barcode specified can be used to confirm the product during work execution. In order to be taken into consideration during product confirmation, you need to enable the “Scanning” checkbox.

In this version you can specify barcodes for any unit of measure. However, if you e.g. need to pick 100 eaches which equals to 1 Pallet you are not able just to scan the barcode of the 1 pallet, because the conversion between each and pallet will not occur. If you need to pick 100 each, youwill still need to scan the barcode of the each UOM and type the quantity of 100.

The following bar codes have been defined for the variants of the Towel:

-

512345678900S for size Small

-

512345678900M for size Medium and

-

512345678900L for size Large

General

If product confirmation has been setup, the warehouse worker cannot proceed without scanning the correct identifier.

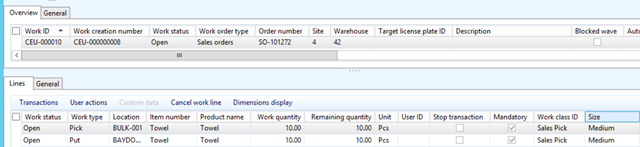

For example, assume that you have a Sales order created for 10 Pcs of medium Towels. All items have been reserved and released to the warehouse. The following work has been created:

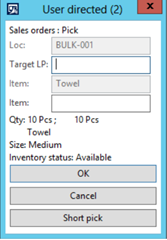

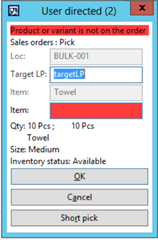

The warehouse worker starts the SO picking process by scanning the work ID and gets the following display

He scans a target license plate and tries to proceed. He gets blocked until he also scans the product identifier, which in this case can be a bar code or a GTIN code.

If he scans a bar code of a variant that is not in the current work (eg. 512345678900L) or an identifier that does not exist he gets blocked with the proper error messages.

Different tables are queried until the scanned identifier can be accepted or declined. The search engine implemented tries first to find a record with that ItemId in the InventTable. If there is not such record, it searches if there is a record in the InvenTable with that NameAlias. Only if this fails it queries the InventItemBarcode table. The last 2 tables that are queried are the CustVendExternalItem and the InventItemGTIN. If a record is retrieved in any of the above searches, no more queries are executed and the validation passes. If not, we get the error.

The same search engine is used to identify the item scanned in the other processes, like PO item receiving, in which it is most likely that the item scanned will be the ItemId of the InventTable.

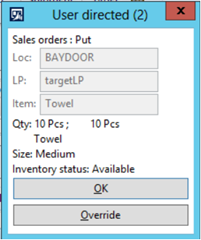

Once he scans the correct barcode (512345678900M), he proceeds with the Put part. Note, that he won’t need to scan the barcode again in this step, as we have only enabled product confirmation for the Pick work type.

In case of a broken bar code / GTIN code, the only way to get unblocked is to contact the warehouse manager and remove the setup from the menu item. There is currently no support like having the supervisor scanning a unique code etc.

Conclusion

The Product scanning confirmation has been a wish place very high on our backlog as it allows a lot more flexibility in setting up your warehouse – allowing you to support a verification step when setting up several items on the same location. Your location setup is more flexible, and you still get a validation that the correct items are setup.

This requirement is accentuated when supporting variant – so it was added to the product together with the development of variants.

The next steps with product scanning confirmation are:

- Adding UOM conversion capabilities for bar code scanning.

- Adding support for batch number confirmation.

- Adding support for serial number confirmation.

- Support for multiple items.

Please give us feedback on our suggested backlog and rate the importance of the above action items.