Practical experiences on implementing the (WHS) warehouse module – Wave Replenishment

In continuation on our experiences with implementing WHS Warehouse management I will go into the findings we had in regards to Warehouse management replenishment.

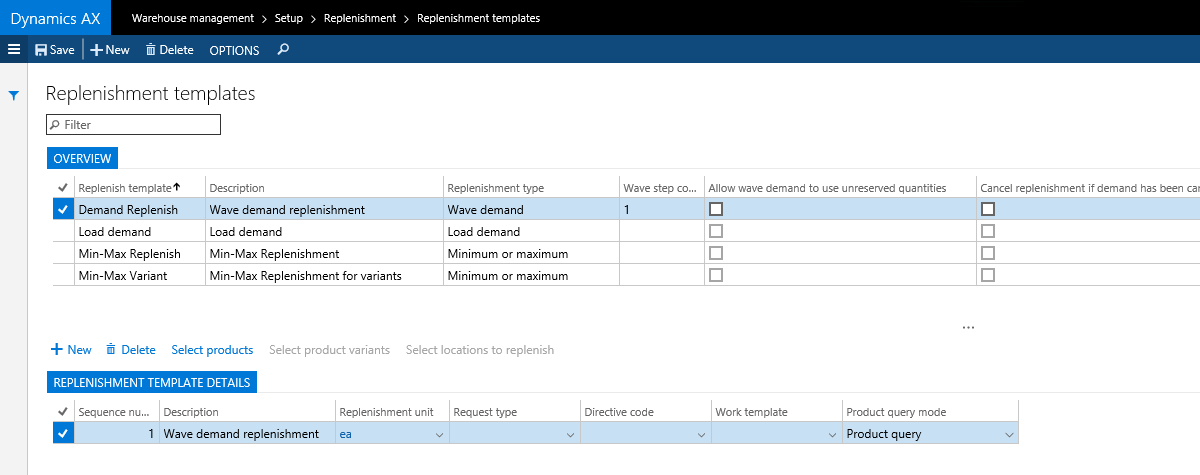

Replenishment starts with the user defining what replenishment strategy to pursue. There are three options: Wave demand, Load demand and Min/max. All to setup under WHS>Setup>Replenishment>Replenishment templates:

Notice I have done some (normal) setup in regards to (Replenishment) Work template and (Replenishment) location directives which I have not shown here. Just keep in mind that Wave replenishment requires both a pick and a put location directive. An unfortunate finding in terms of the "Put" option is that you do not have the option to consolidate where you put the items. I tried to allow for that by adding replenishment as an allowed type to have strategy on - and it appeared to work but please test before going live.

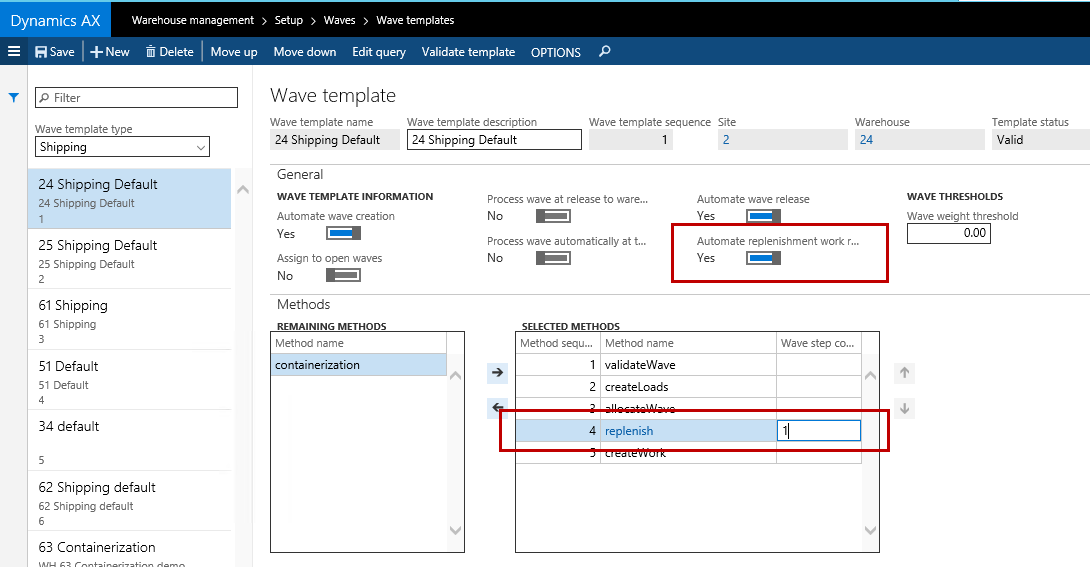

The wave demand works by being triggered during the processing of waves. It requires that the wave template contains the Replenish method and that the Wave code step has a match in the replenishment template (Here it is using “1” as the link):

Notice also the “Automate replenishment work release” – in essence do you want the replenishment work to be created straightaway or do you wish to control when/what is released in terms of replenishment works.

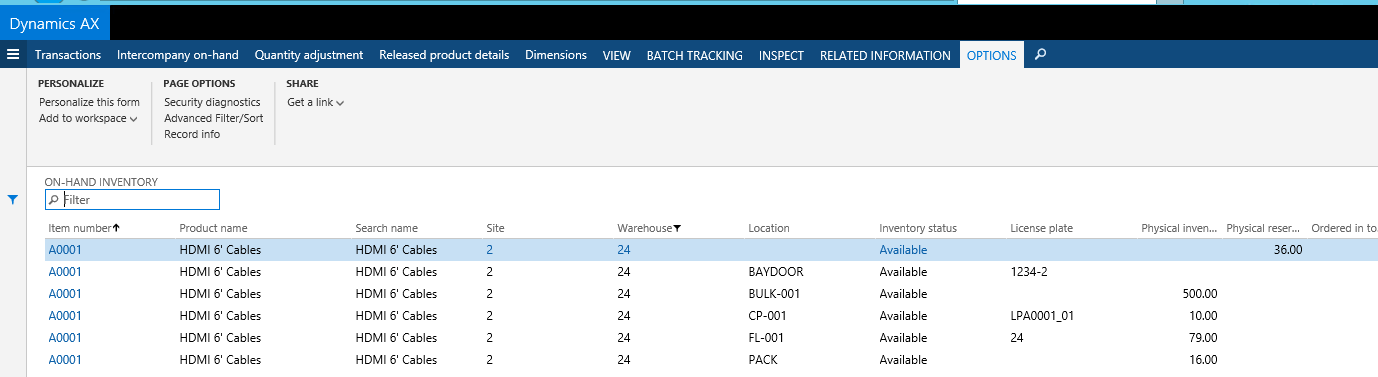

It is quite straight forward, on processing a wave with a shipment that exceeds what is in the picking area (defined in the location directive) it will create a replenishment work in the case that I have the following stock levels in warehouse 24 a sales order that are released into the warehouse will generate a replenishment work:

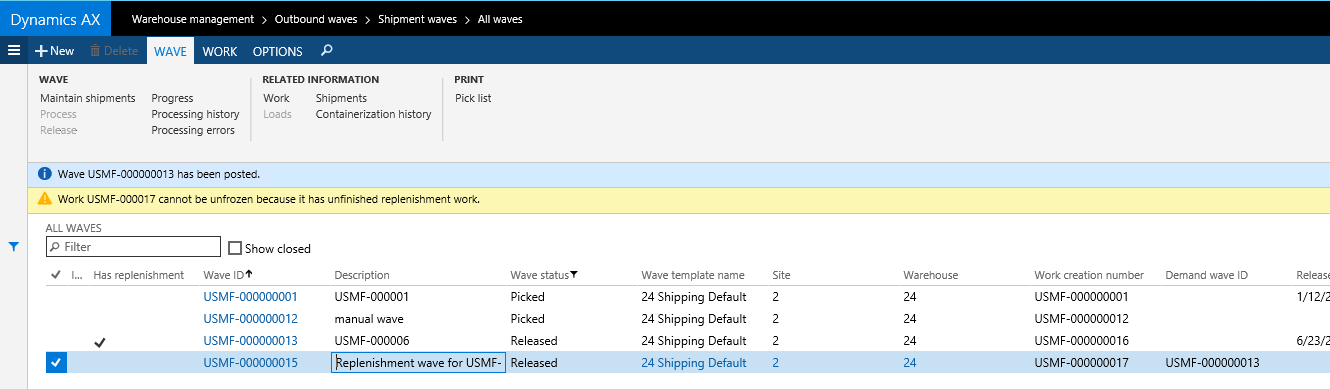

Here I have processed wave USMF-0000013 and it have created a replenishment wave for me and because the automate replenishment release was set to Yes, then the Replenishment wave is released straight away.

Notice the yellow bar informing the user that the work cannot be unfrozen. My wave template tried to release the work straight away and was blocked by the unfinished replenishment work.

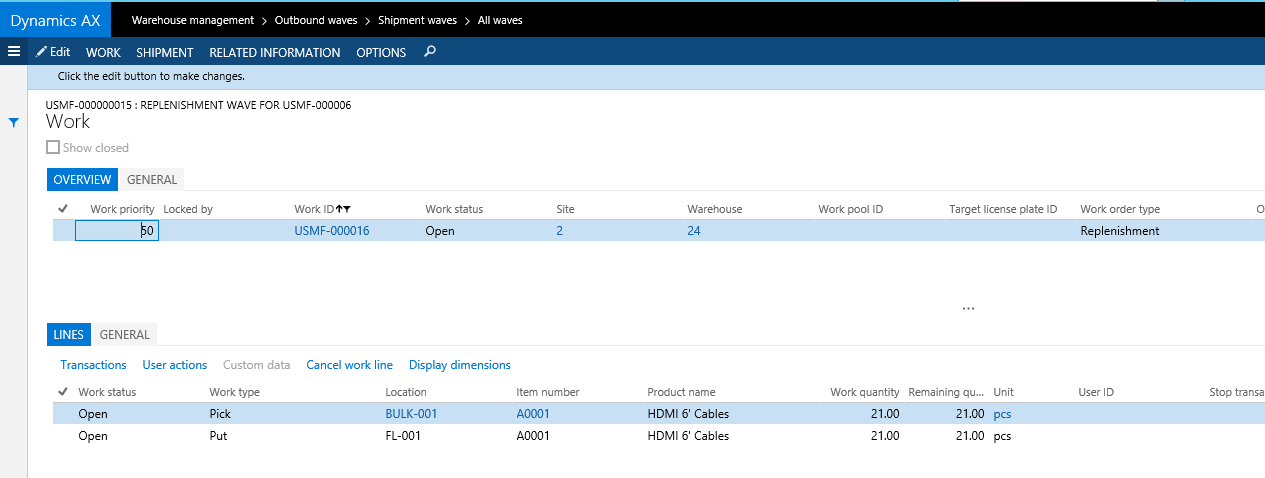

The replenishment work moves the required quantity from in this case bulk to the floor locations based on the location directives:

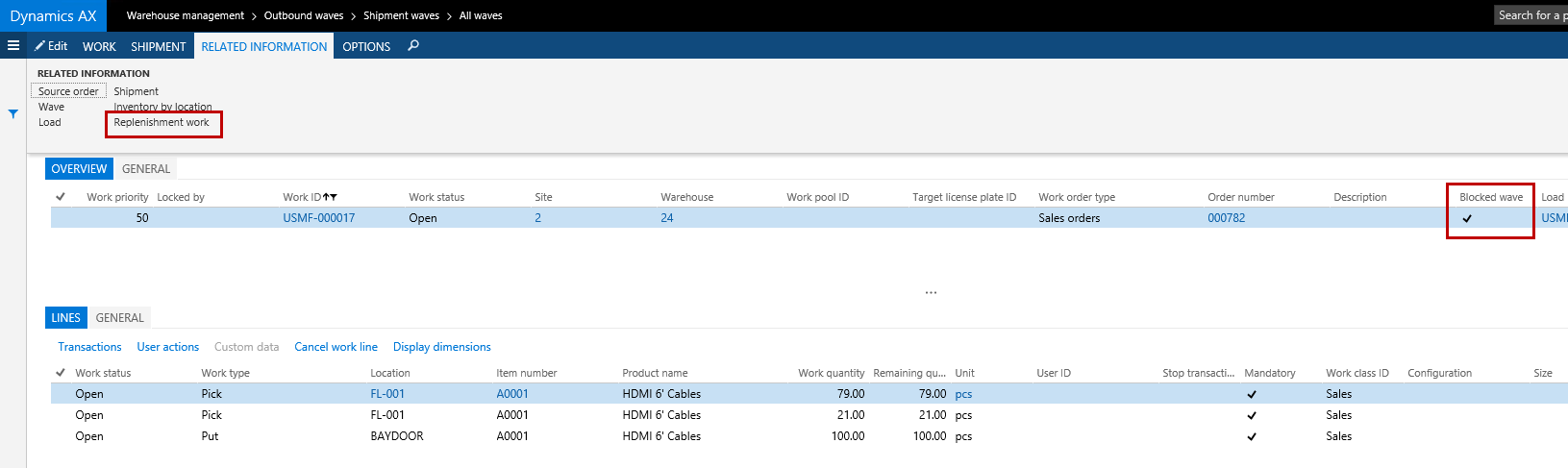

When I look at the blocked sales work I notice that the button “Replenishment work” has opened up:

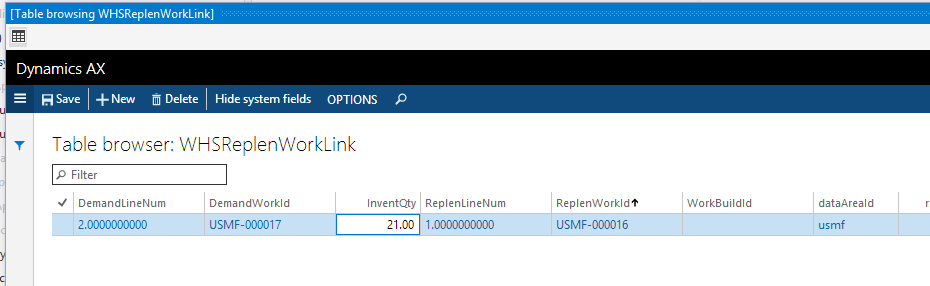

Through this I can see the replenishment work the sales work is tied to. The link between these two works are stored in the WHSReplenWorkLink table:

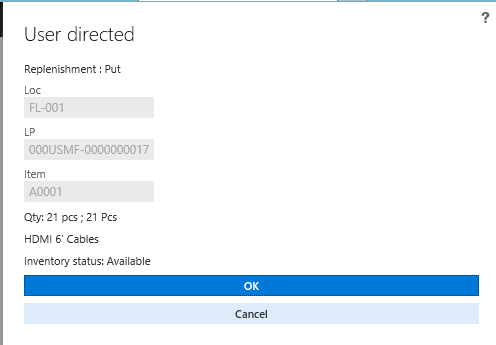

Apart from the ability to jump between the two works having this record also controls the automatic release of the sales work, plus for us there was an unfortunate element that the user could not override the put location of the replenishment work when such a link existed:

But once the replenishment work is completed the sales work is immediately released.

In the next part I will talk to the min/max replenishment