Practical experiences on implementing the (WHS) warehouse module – Min/Max Replenishment

Practical experiences on implementing the (WHS) warehouse module – Min/Max Replenishment

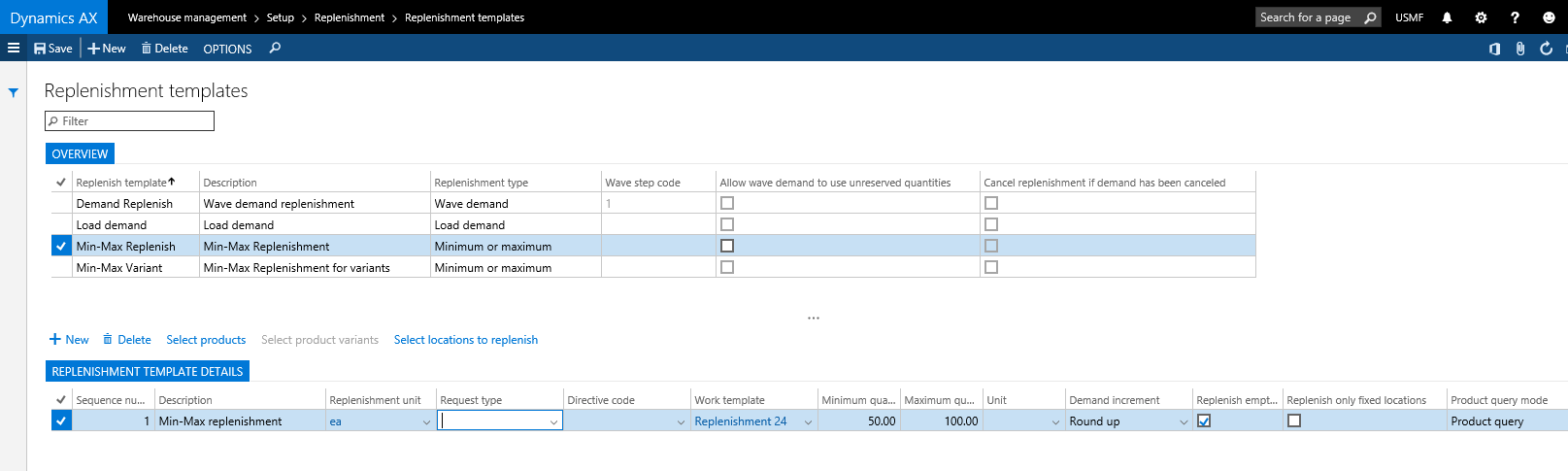

The Minimum/maximum replenishment template works somewhat differently than the previously discussed Wave replenishment. We used these two templates/strategies in combination because the Wave template can handle spikes in outgoing sales work and the Minimum-maximum keeps levels at a certain required level.

The Min-max replenishment does not use put location directives but has for each line a defined set of locations to replenish (“Select locations to replenish”). Also note the field to the far right in the lines that specifies whether the product query is for normal products or for variant items.

The Directive code can be confusing because it is not tied to through the Work template as normal but goes directly to the Location directives. Actually you cannot define a directive code on Replenishment work templates so potentially you will use a work template without a directive code and location directives with.

Note the replenishment unit, if your items are diverse in terms of units, then this should be reflected by adding multiple replenishment lines.

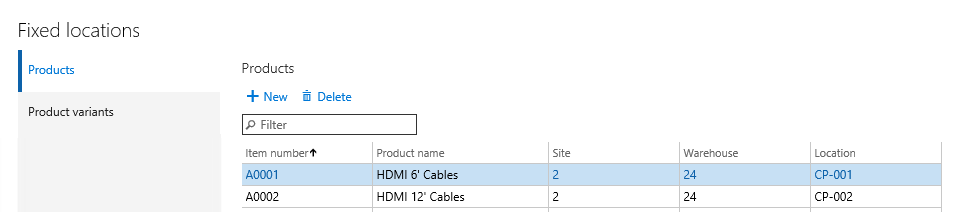

Finally, there is the question of which locations should be replenished. The “Select locations to replenish” will likely merely point toward the picking area. The two check boxes regarding fixed locations defines whether to replenish an empty fixed location and whether to only replenish the fixed location and thus ignore other locations containing the specified item. The fixed locations are defined under Warehouse management>Setup>Warehouse>Fixed locations. More to come regarding fixed locations.

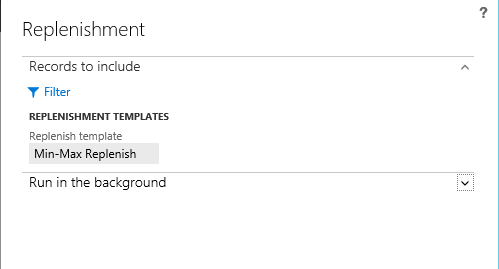

One the Min-max replenishment template has been setup correct the user can initiate the template under Warehouse management>Replenishment>Replenishments which is a very simple periodic job that can be put into batch:

I have defined my Min-max template to run on the three items A0001, A0002 and the newly created A0003. My replenishment template evaluates the Floor (FL) locations and the Web shop (CP) and takes from the BULK area. The template has a min at 50 and a maximum of 100 pcs.

Finally, A0001 and A0002 have fixed locations at CP-001 and CP-002 respectively.

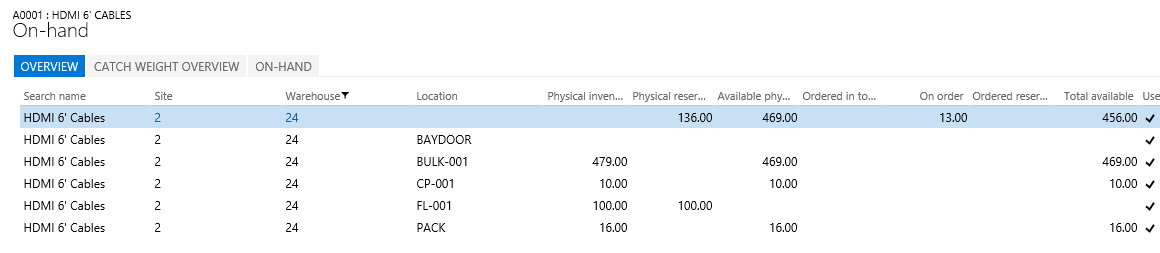

I have the following in stock on A0001:

Notice while I have 100 on the FL-001 they are all physically reserved.

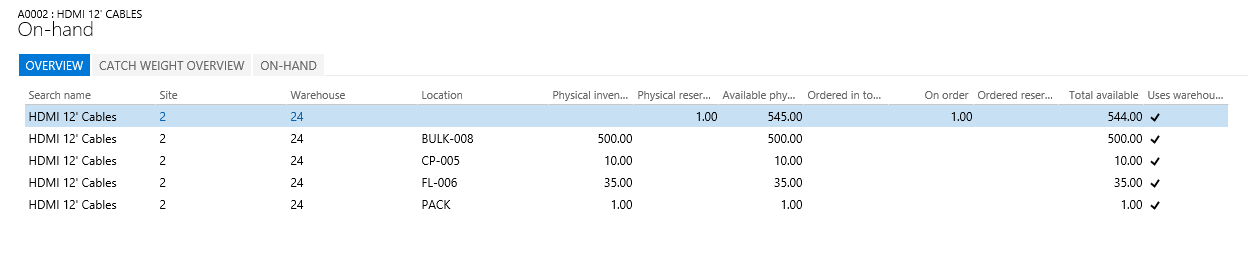

I have the following in stock on A0002:

Notice two locations have less than 50 in quantity, but there is nothing on the defined fixed location (CP-002)

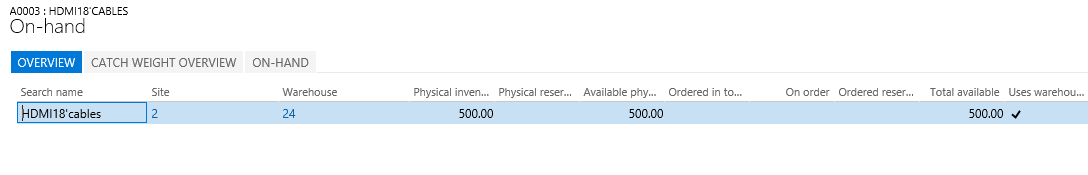

And lastly I have the A0003, nothing in the pick areas only on Bulk:

When I run the min-max replenishment template on these data I get 4 replenishment works:

1 replenishment work for A0001 of a quantity of 90 on Location CP-001

0 replenishment work for A0001 on location FL-001, the replenishment evaluates that there is enough on this location. If the content of the location had been 20 and all reserved I would have seen a replenishment of 80 on this location.

1 replenishment work for A0002 of a quantity of 100 on Location CP-002 (the empty fixed location)

1 replenishment work for A0002 of a quantity of 90 on Location CP-005

1 replenishment work for A0002 of a quantity of 65 on Location FL-005

0 replenishment work for A0003 because A0003 have neither a fixed location nor an existing quantity in the area defined by the replenishment template.

We have had some customer dissatisfaction with the above result. The customer expected that the picking area would be evaluated as one and the quantities would reach the desired level in total in the area. Also the missing replenishment for A0003 is troublesome, we solved this by giving all items a fixed location.