Ask Learn

Preview

Ask Learn is an AI assistant that can answer questions, clarify concepts, and define terms using trusted Microsoft documentation.

Please sign in to use Ask Learn.

Sign inThis browser is no longer supported.

Upgrade to Microsoft Edge to take advantage of the latest features, security updates, and technical support.

Note

Access to this page requires authorization. You can try signing in or changing directories.

Access to this page requires authorization. You can try changing directories.

With KB-3164415 a new mobile device work flow for registration of raw material consumption has been introduced.

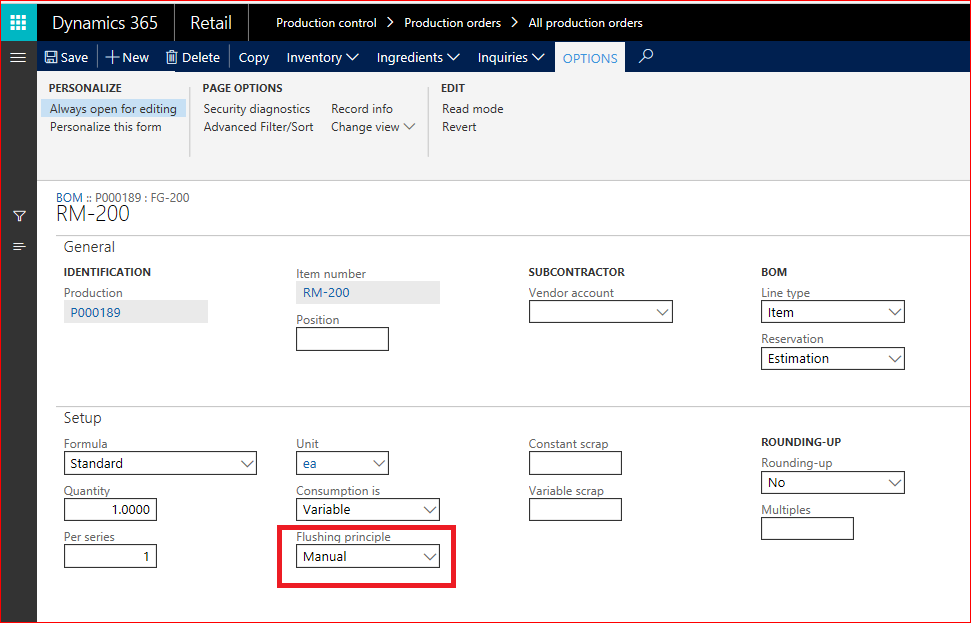

Material consumption, for production or batch orders, is in Dynamics AX done with the use of the production picking list journal. A material can be configured to be consumed either as a manual or automatic process with the use of the Flushing principle on the Bill of material or Formula lines. By selecting the principle Start or Finish it is indicated that materials should be consumed automatically, either by production order Start or when Reporting as finished. By selecting the principle Manual, it is indicated that the user should manual account for the material consumption. The reason why manual registration is sometimes required, is to secure that the actual time of the consumption corresponds with the time of registration, so material traceabiltiy can be maintained. Traceabiltiy is a typical requirement in the food industry, where all food ingredients and packaging materials that are in contact with the food ingredients, must be traceable.

The new hand-held flow works as an interface to the production picking list journal. With the hand-held device the users scans the materials on the locations and accounts for the quantity and dimensions. For each registration a production picking list journal line is created for the production order. When the user confirms the registration as completed the picking list journal is posted.

Let’s walk through a simple scenario that shows how the new work flow is configured and how it works.

The figure below shows a production process that is consuming a batch controlled raw material RM-100. The material is on-hand on location Bulk-001 on license plate PL-1 with two batches b1 and b2 both with a quantity of 100 Lbs. Warehouse work is released and processed for RM-100, picking the material from Bulk-001 to the production input location PIL-01. From the production input location consumption of the material is registered as a manual operation by the machine operator.

First create a new Mobile device menu item with the activity code Register material consumption

Add the menu item to the Production Mobile device menu

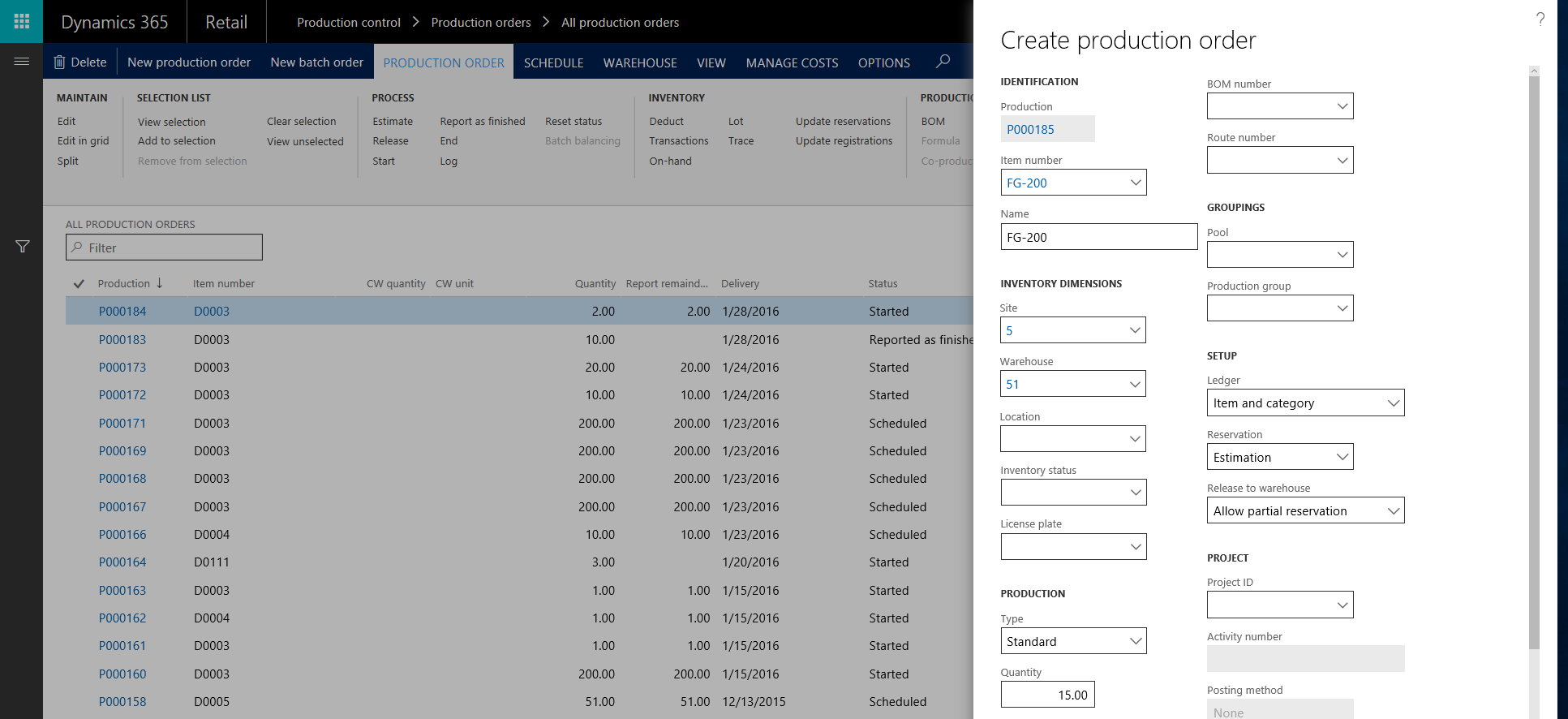

Create a production order for the finished product

The flushing principle on the bill of material line is set to Manual

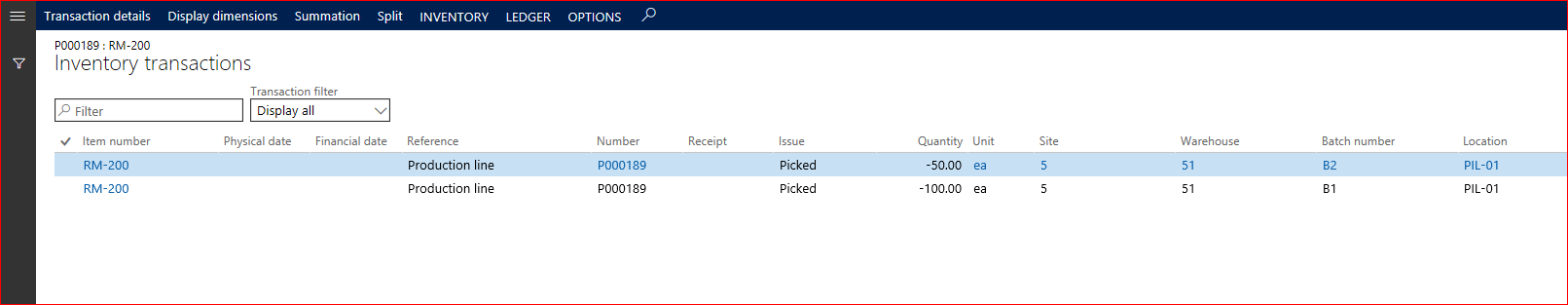

The production order is Estimated and Released and warehouse work is created. After the work is processed the material is in status: Picked at the production input location.

After the production order is Started, material consumption can be registred with the new work flow. We start by consuming 25 ea of Batch B1 and after that 50 ea of batch B2:

Some additional comments to the flow:

Ask Learn is an AI assistant that can answer questions, clarify concepts, and define terms using trusted Microsoft documentation.

Please sign in to use Ask Learn.

Sign in